Your Cart is Empty

Luggage

Apparel

events

The Mosko Blog

Assembly on a larger scale and shipping

March 30, 2022

Assembly on a larger scale and shipping

This last week was a busy one. At Mosko Moto’s expansive global shipping facility in Portland we set up an assembly line with hired workers and loaded for bear. From our little early assembly experiment at Pete’s house we were able to figure out some devices and processes that could be scaled up to do a larger amount of product. Luckily putting the plates (made in portland) on the bags (made in Vietnam) is not very complicated, it just requires a soldering iron, a hammer, and a drill. It still took us almost a week to put this stuff together. Our warehouse was kind enough to give us an unused corner to work in. Our warehouse is about 1.5 hours from Hood River so it was early mornings and long days. It felt great to get this hurdle completed though.

7am, back of the warehouse about to unload HDPE plates, and 10s of thousands of washers and screws- and many of my tools needed for assembly. We really need a covered trailer.

We got a pretty good system going, a finished pannier would pop off the line about every 5mins when we were really cooking- then it would be break time and everyone would walk away.

Melting station. Here is one of our helpers using a soldering iron to place the holes in the bag that exactly match up to the HDPE plate. I built a special board that protected the dry bag inside from the soldering iron. The soldering iron works well because it seals the fibers in the fabric while it is making the hole.

At the next station registration screws are inserted.

This next board had to be sturdy so it was made out of 1″ plywood. We would slide the bag on, pull the T-nuts into their respective holes with a hammer and screw in the finished black stainless steel screws. The sturdy board allowed us to drill the screws in and not damage any of the other layers.

Bowls from my kitchen containing black-oxide stainless steel screws, washers and T-nuts.

While that was going on we had people sorting and bagging aluminum pucks, screws and washers.

Also MOLLE stick packets.

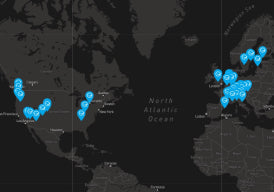

Once Pete got back from a moto rally in Taos he started setting up the shipping line. It was a little more efficient than doing it in his living room. The shot below are all orders that are being picked and packed as they move down the rollers. Those boxes are currently fanning out across the continent via our fleet of Mosko Moto delivery vans.

Here’s Pete pretending to be busy so i don’t put him on the assembly line.

Now all our stock has been officially entered into our warehouse’s system so they will take over shipping for us. We just had to get everyone’s preorders out as soon as we could, so we did it manually at first. Most of the orders that we have taken thus far have been shipped out so expect something on your doorstep!

Plenty of fall riding season still left so we look forward to seeing pictures and getting feedback.

Andrew and Pete.

Leave a comment

Comments will be approved before showing up.

Warranty and Crash Replacement

We never cut corners during development or manufacturing, so we stand behind our products. If one fails due to a problem with materials or workmanship, we’ll make it right.

Your are successfully subscribed for email notifications.

Notify me when available

We will send you a notification as soon as this product is available again.

Your email is required

We don't share your email with anybody

x