Your Cart is Empty

Luggage

Apparel

events

The Mosko Blog

Scouts, Hoods, Shows, & Holidays

March 30, 2022

Scouts, Hoods, Shows, & Holidays

December 8, 2016

Belated Happy Thanksgiving and Happy Holidays from the Mosko Team!

This time of year we’re deep in product development, working on new designs which we hope to introduce in 2017. Although in reality, we’re running out of time, and some things may not make it. But we’re doing our best.

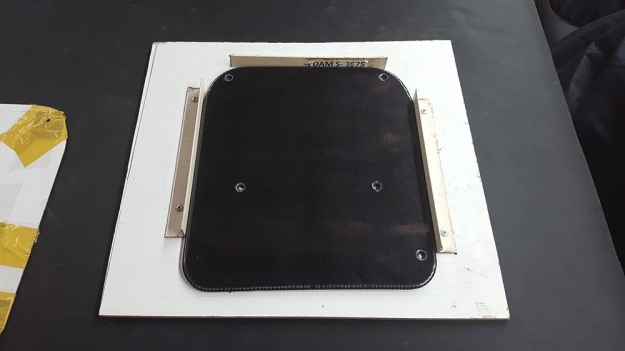

Scout 25 Pannier v2.0

Lots of progress on the new Scout pannier. This replaces the current Scout 25, which uses the same wedge-mount system as the Backcountry 35. The Scout 2.0 will have an all-new aluminum mount that stays connected to the bike, with a removable inner drybag. This will be a minimalist pannier at a lower price point, and will be substantially lighter than the fully-featured Backcountry.

We have a new prototype to play with.

The aluminum plate connects to a pannier rack using the same pucks as the Backcountry system.

The harness connects to the plate using these metal clips, which push through laser cut slots on the aluminum plate.

In the current version, the metal clips are interfering with the pannier rack, so Lee designed a stamped recess for the clip to seat in.

There’s a potential wear-point where webbing passes through the aluminum plate. The aluminum would eventually saw through the webbing.

Lee added small bump-outs in the cleat recession to support the buckle and prevent the webbing from rubbing directly on the aluminum.

The Scout is compatible with Rotopax.

Andrew took the latest prototype out for a test ride. After a half-day of riding, wear-points were already obvious on the back of the drybag. These are caused by the mounting bolts and washers rubbing against the vinyl. We’re adding a polyethylene sheet to the back of this bag to prevent damage.

We’re also adding a (probably optional) MOLLE panel which connects to the aluminum plate, and offers a place to store things that we normally don’t want inside the drybag, like water, gas, etc.

We made a quick & dirty mockup in the shop.

The top of the MOLLE panel connects with metal clips, which will seat in two notches that we’ll add to the aluminum plate.

The MOLLE panel fits two small MOLLE pouches for fuel bottles or other fluids, or a single large MOLLE pouch for a hydration bladder, tools, tubes, etc.

With the drybag in the harness, the drybag sits on the outside of the MOLLE accessories, and the side-straps compress everything tight against the bike.

Here’s what it looks like mounted on Andrew’s KLR before the test ride.

We’d like to get this system into the $350-400 range, but we’re getting a little concerned about price-creep. There are a lot of individual pieces: an 8-piece puck kit, two laser cut and stamped aluminum plates, two attachment harnesses, two removable MOLLE panels, two removable drybags… it’ll be interesting to see where the final costs come in. Regardless, we’re really digging this new system.

Hood Tank Bag

The ‘Hood’ is the new version of the ‘Hatch’ tank bag, our welded-seam, waterproof tank bag concept. We ditched the kayak hatch in favor of a clam-shell lid design, and it became the Hood.

Originally we planned to have a map pocket that attached to the outside, but instead we’re changing the entire top of the bag to be one large map pocket with access from inside the bag. That change will happen on the next prototype. Right now it’s just a cell phone pocket.

There’s a waterproof aux cable pass-through for headphones.

Between the base and the lid is this little rain gutter. Water that tries to creep up the side of the bag while riding hits the rain gutter and slides back down.

A clear headlamp pocket on the front of the bag, to illuminate the interior. This will change to a zipper closure instead of elastic.

We took the Hood proto down to the Bingen car wash for testing. It works! We could clearly see where water crept up the side and stopped at the rain gutter. In the next revision, the clam-shell lid will come all the way down to the bottom of the bag, which will reduce the amount of water creep substantially.

Next, we ran around the Gorge and Portland test fitting the bag on a bunch of bikes. This bag is harder to fit than the Nomad, because it has PE stiffeners in the sidewalls, so it doesn’t conform to the shape of a tank as easily. This bag will not fit on aftermarket enduro-style tanks with a gas cap vent tube. It’s designed for OEM tanks with gas caps that sit flat on the tank and have built-in venting.

1200GS/A

F800GS/A

1190

1290

1150

650GS

Our conclusion is that the bag is too big. We’re removing width/length, and also changing the shape to make it a bit narrower. This is going to be a cool bag!

Lee’s Trip to Vietnam

Lee just returned from two weeks in Vietnam, working with our factory to complete our spring production order for existing bag models (not new product). Production is complete and will be shipping in the next few weeks. This will be the first year we’ve started the Spring season with everything in stock.

Lee also rented a scooter and went exploring around southern Vietnam for a few days, checking out the sights.

Nomad Tank Bag

We’re waiting on a final Nomad tank bag prototype with zipper revisions, but in the meantime, we found a hydration bladder we like from Platypus. It’s the 1.8L version, pictured on the right below. It fits perfectly in the bag, and fills from the bottom.

Long Beach Motorcycle Show

Ash, Dusty, and I just returned from the Long Beach International Motorcycle Show. This is by far the largest show we attend, and it’s always a blast. This was our first time with a 10×20 booth (normally we get a 10×10), our first time with more than one display bike at an indoor show (we had three), and our first time with three people working the booth. A very fun weekend and a great show! We set a new record for orders.

Amazingly, we discovered on day two that they allow dogs in the show, so Brady made lots of new friends.

We met a customer with a broken MOLLE stick. That’s the very first one we’ve ever heard of breaking, and I realized we’d never actually tried to break one ourselves. So we did. It’s not easy. The stick finally snapped after working it back and forth a few times. Conclusion: the broken one our customer experienced was almost certainly a molding defect.

Cool helmets.

The Metal Mulisha provided entertainment.

BMW Atacama bags were on display on a really cool-looking black 1200GS in the BMW booth, where we caught up with Ken Engleman from the BMW Motorcycle Owners Association.

Big thanks to Rob Kirby for loaning us his GS1200 and Husky 501 as display bikes. Check out this cool connection system he made for the rear straps on the Reckless 40.

The strap goes between the fender and the plastic subframe, so it’s trapped in place and can’t slide forward. Great idea Rob!

Somehow, on the way out of LA, trying to beat the traffic with a 4:30am departure and foggy brains, we managed to run out of gas. Handy to have a bike in the trailer.

Back in the gorge, we stopped at the local freight warehouse to ship all our show supplies to New York for the motorcycle show, which is happening this weekend. Dusty will be there working the show. If you’re in the area, stop by and say hi!

Mosko offices will be closed for the Holidays from December 24th to January 3rd. We’ll be out adventuring!

Leave a comment

Comments will be approved before showing up.

Warranty and Crash Replacement

We never cut corners during development or manufacturing, so we stand behind our products. If one fails due to a problem with materials or workmanship, we’ll make it right.

Your are successfully subscribed for email notifications.

Notify me when available

We will send you a notification as soon as this product is available again.

Your email is required

We don't share your email with anybody

x